R-STUDS Metric Threaded Rods - Steel Class A2, Flat Head

A2 stainless steel threaded rod for outdoor and damp conditions

Technical Data Sheet

R-STUDS Metric Threaded Rods - Steel Class A2, Flat Head - Technical Data SheetFeatures and benefits

- Threaded rod made of A2 stainless steel for outdoor use and in damp conditions

- High-performance bonded anchors offer high load-bearing capacities

- Can be post-installed through fixture in some cases. (Consult technical advisory service)

- Flat head for quick manual installation without a setting tool

- Necessary for use in copy-eco system - reinforcement of suspension rod in large-panel construction systems

Product information

Size |

Product Code |

Anchor |

Fixture |

|||||

Diameter |

Length |

Max. thickness tfix for: |

Hole diameter |

Max. thickness tfix for: |

||||

d |

L |

hnom, 6d |

hnom, 12d |

df |

hnom,min |

hnom, 12d |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

M10 |

R-STUDS-10330-A2FL |

10 |

330 |

258 |

198 |

12 |

248 |

198 |

M12 |

R-STUDS-12140A2FL |

12 |

140 |

53 |

- |

14 |

45 |

- |

R-STUDS-12200-A2FL |

12 |

200 |

113 |

41 |

14 |

105 |

41 |

|

R-STUDS-12220-A2FL |

12 |

220 |

133 |

61 |

14 |

125 |

61 |

|

R-STUDS-12250-A2FL |

12 |

250 |

163 |

91 |

14 |

155 |

91 |

|

R-STUDS-12260-A2FL |

12 |

260 |

173 |

101 |

14 |

165 |

101 |

|

R-STUDS-12280-A2FL |

12 |

280 |

193 |

121 |

14 |

185 |

121 |

|

R-STUDS-12330-A2FL |

12 |

330 |

243 |

171 |

14 |

235 |

171 |

|

R-STUDS-12350-A2FL |

12 |

350 |

263 |

191 |

14 |

255 |

191 |

|

R-STUDS-12380-A2FL |

12 |

380 |

293 |

221 |

14 |

285 |

221 |

|

R-STUDS-12400-A2FL |

12 |

400 |

313 |

241 |

14 |

305 |

241 |

|

R-STUDS-12440-A2FL |

12 |

440 |

353 |

281 |

14 |

345 |

281 |

|

R-STUDS-12490-A2FL |

12 |

490 |

403 |

331 |

14 |

395 |

331 |

|

R-STUDS-12500-A2FL |

12 |

500 |

413 |

341 |

14 |

405 |

341 |

|

R-STUDS-12550-A2FL |

12 |

550 |

463 |

391 |

14 |

455 |

391 |

|

Applications

- Fastening with bonded anchors

- Supports

- Barriers

- Racking systems

- Consoles

- Railings

- Window elements

- Scaffolding

- Heavy machinery

- Facades

- Copy-eco systems

- Cable trays

- Curtain walling

- Formwork support systems

Installation guide

- Drill hole to the required diameter and depth for stud size being used.

- Clean the hole thoroughly with hand pump and hole brush

- If required, insert the mesh sleeve into position

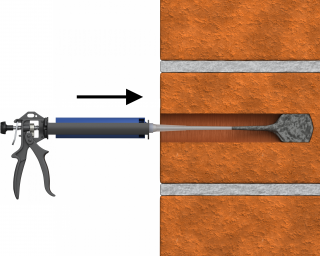

- Fill hole with the required resin to the recommended fill level. (Follow the relevant instructions for the resin product)

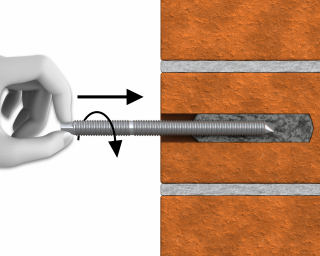

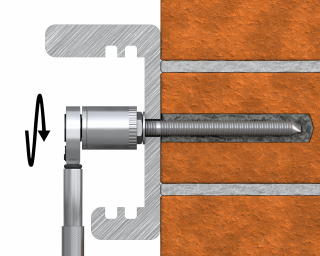

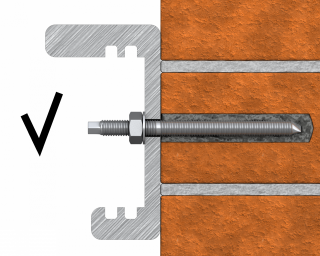

- Insert the threaded stud slowly and with a slight twisting motion, until the required embedment depth is reached

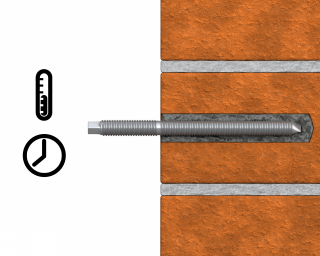

- Leave undisturbed until curing time of resin has elapsed

- Attach fixture and tighten the nut to the required installation torque